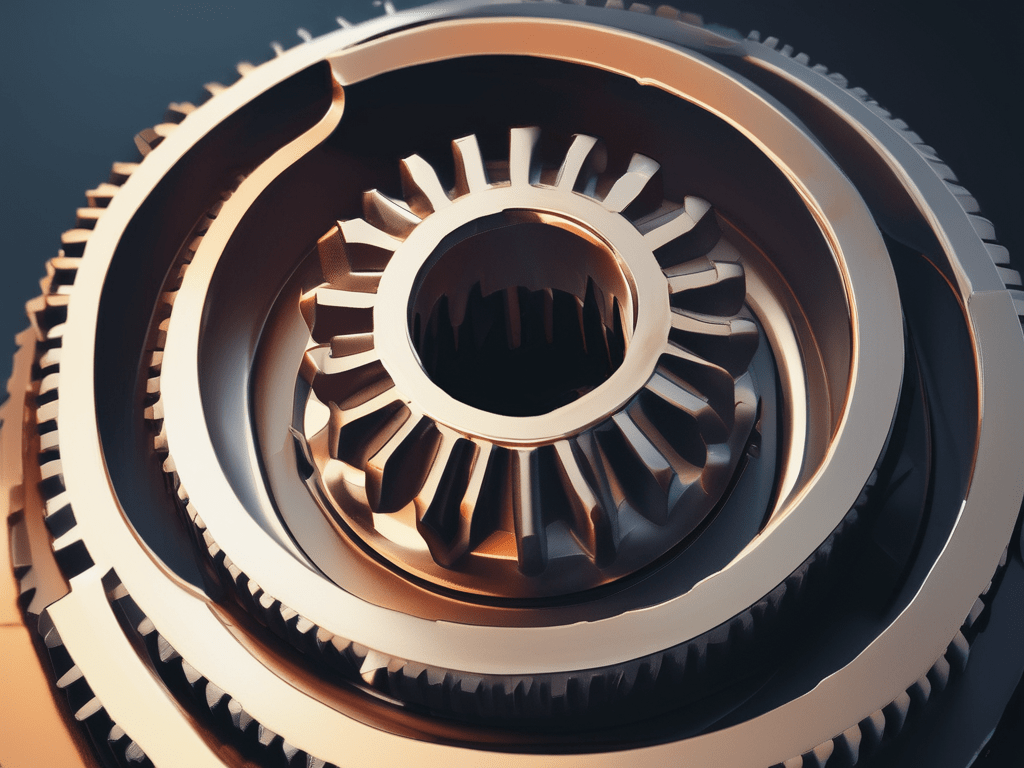

Introduction to Bevel Gears

Bevel gears are an essential component in various mechanical systems, used to transfer power between shafts that are at an angle to each other. Unlike straight gears, which operate parallel to the shaft, bevel gears can mesh at any angle, usually at 90 degrees. They are commonly found in applications ranging from automotive differentials to industrial machinery and even household appliances. The intricate design and manufacturing of bevel gears require precision and expertise, making the role of a bevel gear manufacturer crucial in ensuring optimal performance and reliability.

Types of Bevel Gears

Bevel gears come in several types, each suited for different applications and requirements:

- Straight Bevel Gears: These gears have straight teeth and are typically used for low-speed applications. They are simple in design and cost-effective but may produce more noise and vibration compared to other types.

- Spiral Bevel Gears: Featuring curved teeth, spiral bevel gears offer smoother and quieter operation. They are commonly used in high-speed and high-load applications due to their efficiency and durability.

- Hypoid Gears: These are similar to spiral bevel gears but with an offset between the shafts. Hypoid gears provide a smooth and quiet operation and are used in automotive differentials and other heavy-duty applications.

- Zero Bevel Gears: Also known as straight bevel gears with zero bevel angle, these are used for applications requiring a direct 90-degree shaft alignment with minimal noise and wear.

The Role of a Bevel Gear Manufacturer

A bevel gears manufacturers in India plays a critical role in the production of these specialized components. The manufacturing process involves several key steps:

- Design and Engineering: The first step involves designing bevel gears to meet specific application requirements. This includes determining gear ratios, angles, and material specifications. Advanced software and simulations are used to ensure precise design and performance.

- Material Selection: Choosing the right material is crucial for the durability and performance of bevel gears. Common materials include steel, stainless steel, and various alloys. The selected material must withstand the operational stresses and environmental conditions of the application.

- Cutting and Shaping: Bevel gears are machined using advanced cutting techniques such as hobbing, shaping, or grinding. The gear teeth must be cut with high precision to ensure proper meshing and minimal wear.

- Heat Treatment: To enhance the strength and hardness of the gears, heat treatment processes like carburizing or quenching are employed. This ensures the gears can withstand high loads and resist deformation.

- Quality Control: Rigorous quality control is essential in bevel gear manufacturing. This includes checking for dimensional accuracy, gear tooth profiles, and overall gear performance. Manufacturers use precision measuring tools and testing equipment to ensure each gear meets the required standards.

- Assembly and Testing: After manufacturing, bevel gears are assembled into gearboxes or other mechanical systems. Testing is conducted to verify the gear’s performance under operational conditions and to identify any potential issues.

Applications of Bevel Gears

Bevel gears are versatile and used in various applications across different industries:

- Automotive Industry: In vehicles, bevel gears are used in differentials and transmission systems to transfer power between the drive shaft and wheels, allowing for smooth and efficient operation.

- Industrial Machinery: Bevel gears are found in machines such as conveyors, mixers, and pumps, where they help in changing the direction of motion and transmitting power.

- Aerospace: In aerospace applications, bevel gears are used in flight control systems and landing gear mechanisms, where precision and reliability are crucial.

- Consumer Goods: Bevel gears are also present in everyday appliances like washing machines and power tools, contributing to their functionality and efficiency.

Choosing the Right Bevel Gear Manufacturer

Selecting the right bevel gear manufacturer is vital to ensuring high-quality gears that meet your specific needs. Key factors to consider include:

- Experience and Expertise: Look for manufacturers with a proven track record in bevel gear production. Their experience will ensure that they can handle complex designs and provide reliable products.

- Technological Capabilities: Advanced manufacturing technologies and equipment are essential for producing precision bevel gears. Ensure the manufacturer uses state-of-the-art tools and techniques.

- Quality Assurance: A reputable bevel gear manufacturer should have robust quality control processes in place. This includes rigorous testing and inspection to guarantee the performance and durability of the gears.

- Customization Options: Depending on your application, you may need customized bevel gears. Choose a manufacturer that offers design and customization services to meet your specific requirements.

- Customer Support: Good customer support is crucial for addressing any issues or concerns that may arise. A reliable manufacturer should provide timely assistance and support throughout the product lifecycle.

Conclusion

Bevel gears are critical components in many mechanical systems, and their effective performance depends on precise manufacturing and expert design. As a bevel gear and Spiral Bevel Gear Manufacturer, it is essential to focus on quality, innovation, and customer satisfaction to deliver high-performance gears that meet diverse industry needs. By understanding the intricacies of bevel gear production and choosing a reputable manufacturer, you can ensure that your applications operate smoothly and efficiently.